Your basket is currently empty!

Wadden Systems Inc. is a company that makes flavours for soft serve ice cream and other flavouring systems.

It was started in 1993 by Rita Wadden, who was a pioneer in the industry. The company made a new system which enabled soft serve ice cream to be transformed into 24 (or more) flavours of soft serve, and it is still one of the leaders in the industry today.

About Systems Wadden

Our family has been involved in the Dairy Bar & Ice Cream Store industry for more than 50 years, opening well over a thousand Ice Cream Store & Dairy Bars in that time frame.

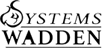

We were around when the very first automatic soft serve ice cream machines out-rolled for the world to see. We were also present at the inception of Slush machine. Throughout the years, our family has established itself internationally as an innovator in the industry.

The last half century in the Dairy Bar & Ice Cream Store industry has seen many trends come and go, some of them with considerably more staying power than others. In the intervening years since 1953, our family has witnessed these many developments in the industry not only from the perspective of equipment & supply companies, but as operators of retail Ice Cream Stores as well.

We know from first-hand experience that while retail operators want to remain competitive in their new menu offerings, many feel strangled for space as it is and have, for the most part, very limited available capital for new equipment expenditures.

Having learned over the years which core menu items are the greatest profit-yielders, we have focused most of our energy on developing creative ways to increase the volume of sales on those high profits items, without needlessly tying-up capital in lots of equipment or squandering precious square footage. Thus, it is with a measure of pride that we introduce to you our uniquely profitable solutions for your business.

24 Flavours in the press

Here are a few newspaper articles from the northeast that mention the 24 Flavour System. Our particular interest is a feature story on the Harrisburg, Pennsylvania area’s favorite Ice Cream stores. Although there are only two customers in the entire area, the stores with 24 Flavour System came in first and third out of thirty-one stores! (second place went to a store that serves hard ice cream only). The 24 Flavours concept allowed those customers, in their first year of operation, to out-perform all the long established ice cream outlets in the greater Harrisburg area.

Flavour Extract Nutritional Content

Nutritional Labeling and Education Act (NLEA)

Nutritional Profiles

Flavouring extracts, essential oils, colors, spices and other aromatic chemical compounds by definition are exempt as per the rules for compliance as published in the Federal Register on January 6, 1993, (Volume 58, No.3).

The strength and usage of such material in finished food products are determined under normal usage to fall under the published guidelines to be regarded as zero(0).

| Total calories | Less than 5 calories |

| Total fat | Less than 0.5 mg |

| Cholesterol | Less than 2 mg |

| Carbohydrate | Less than 1 mg |

| Protein | Less than 1 mg |

The flavour extracts have either no nutritional value or level of no nutritional significance in respect to vitamins, minerals or fiber content.

| Fat content | 0.00 |

| Carbohydrates (In the form of sugar) | 0.00 |

Each product has some caloric content derived from the solvents used in the production of the flavouring such as ethyl alcohol, propylene glycol, glycerin, etc. Also, some caloric content is derived from the essential oils, botanicals or aromatic chemicals in the flavouring.

This caloric content ranges from 59-90 calories per 100 grams of material. Based on the usage strength of these additives, the value of these additives on a per serving basis would be negligible or less than of nutritional significance.

Using the most caloric extract in a 24 flavors cone, it is 1.36 calorie.

The F.D.A. regulations are directed toward the nutritional value of the food consumed. Your processing or the consumer’s preparation of the final food product may alter the nutritional value of our products in your customer’s food product.